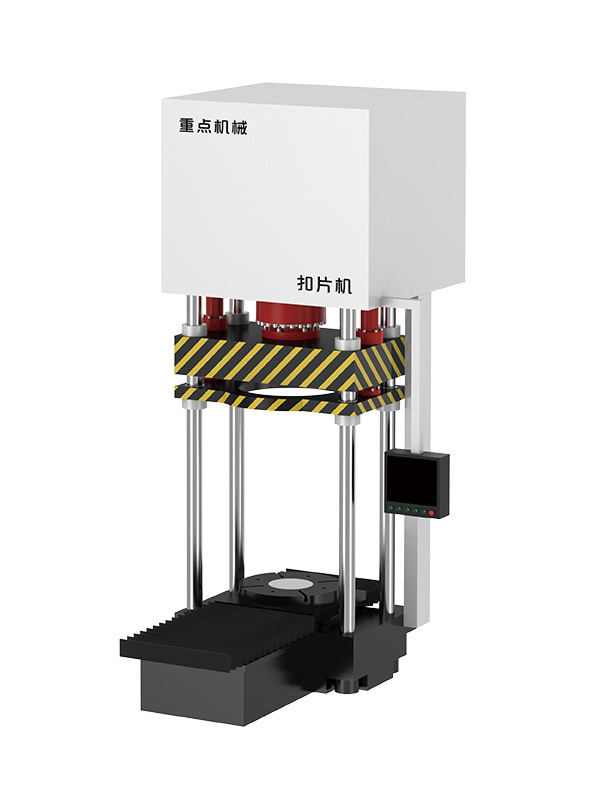

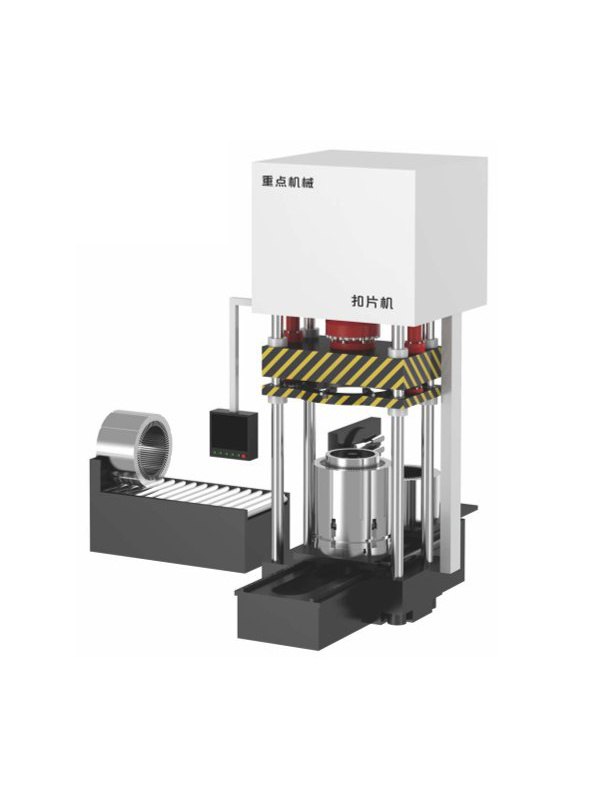

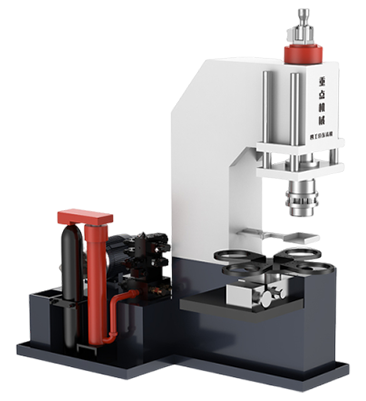

Product Series

With customized designs, diversified products, and in-depth interpretation of industry policies, we build a unique personalized service system for our customers.

Taizhou Zhongdian

Machinery CO.,LTD

More than 10 years of production experience

More than 100 partners

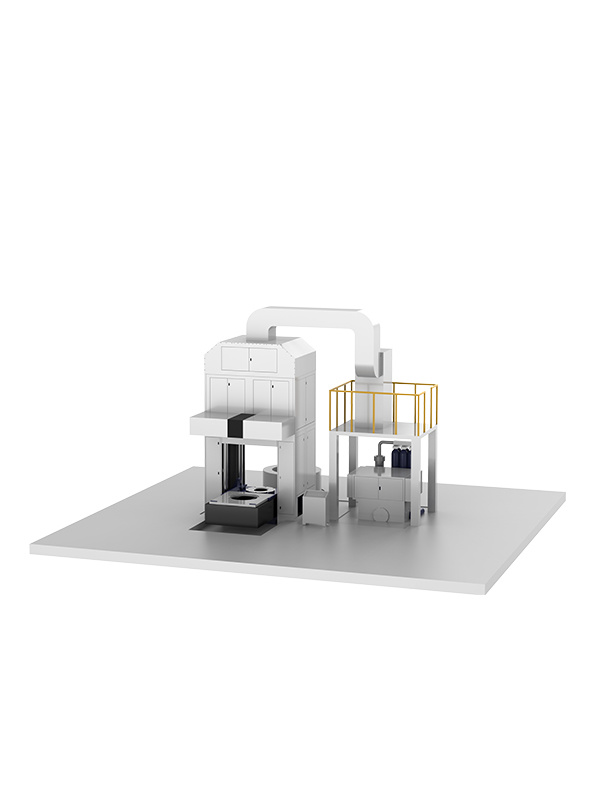

Solutions

With customized designs, diversified products, and in-depth interpretation of industry policies, we build a unique personalized service system for our customers.

Why Choose Us

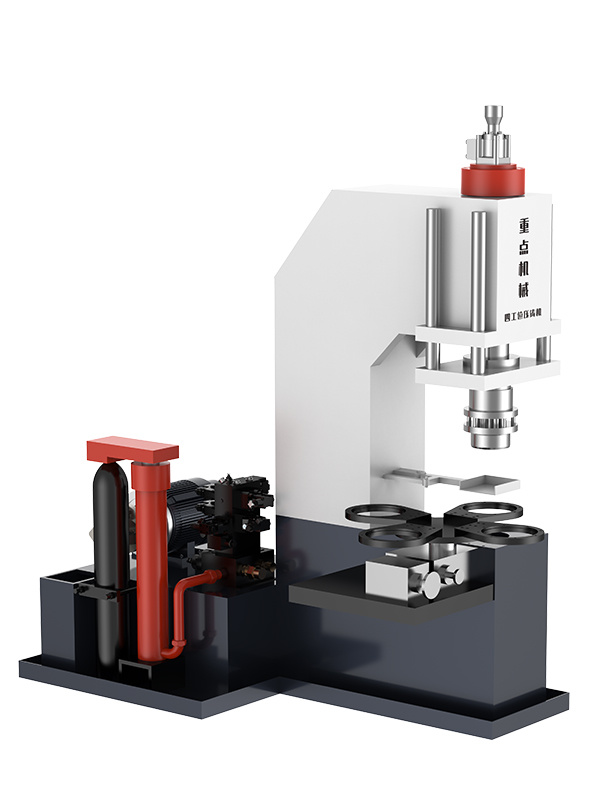

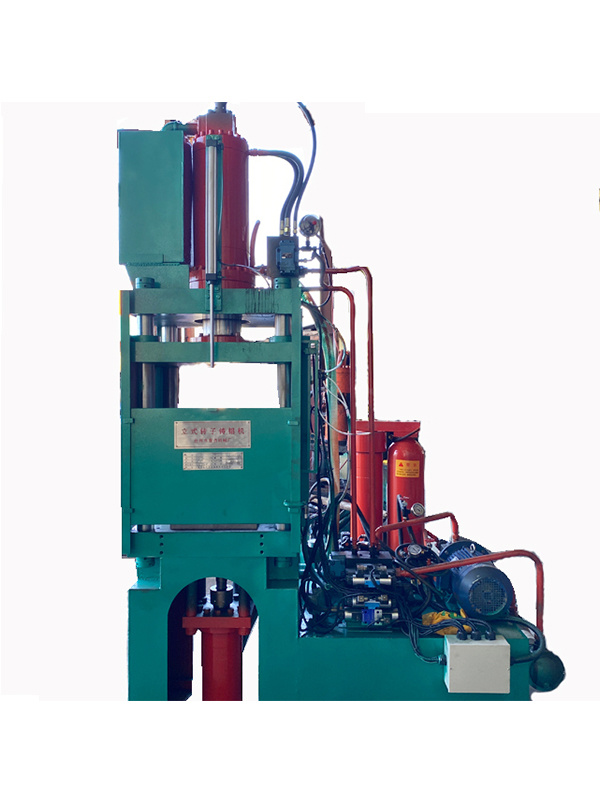

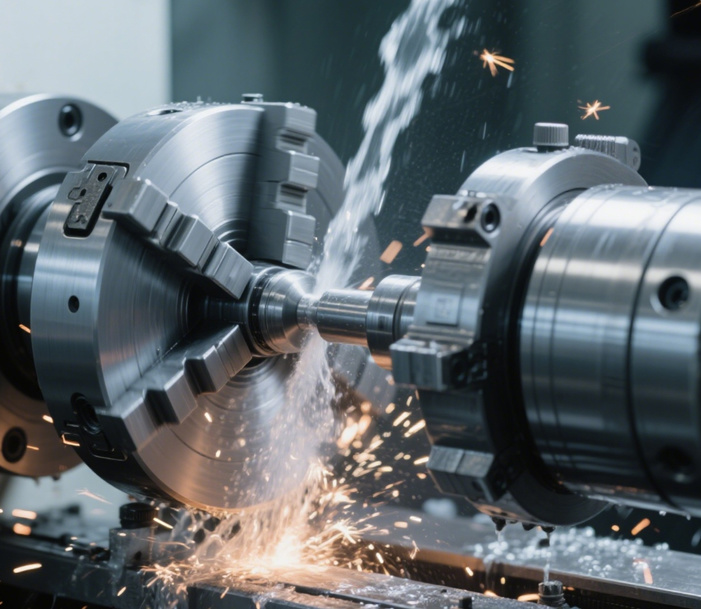

Our factory has strong technical force, excellent production equipment, complete testing methods, and a complete quality assurance system. Various hydraulic machinery produced by our factory are favored by customers for their small size, good performance, low power consumption, low noise, high technical content, high work efficiency, and affordable prices.

Customize Now →

Strong Technical Force

Complete Quality Assurance System

Choose Key Machinery

Choose Peace of Mind

If you have any questions, please feel free to contact us.

Service Hotline:+86-13906586333

E-mail:shengzhou20200626@163.com

Blog

Stay updated on our latest news

2022-01-12

Introduction to the maintenance and care of hydraulic cylinders

2021-12-28

How much do you know about the basics of hydraulic cylinders?

2021-12-13

Detailed Explanation of Hydraulic Cylinder Types and Parameter Design