Products

R & D and production of various hydraulic machinery

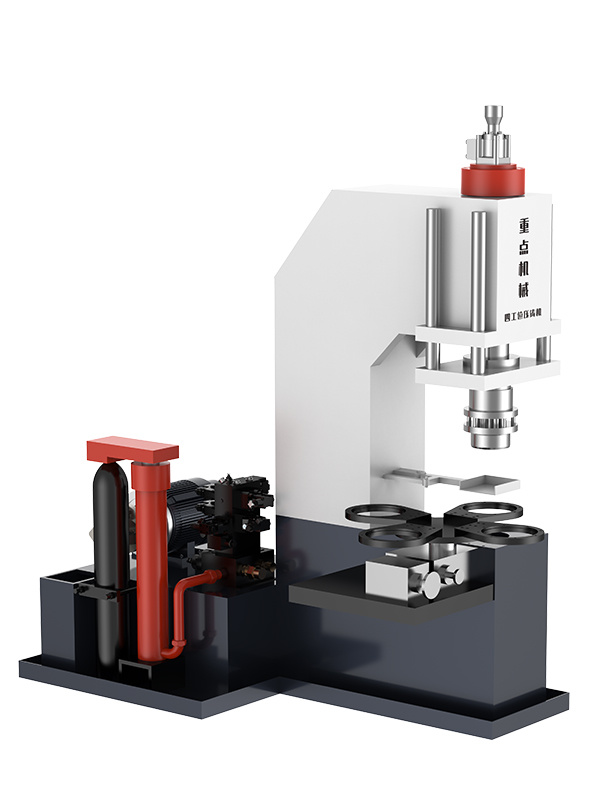

Fully automatic dual-station aluminum die casting machine

This device is a dedicated aluminum casting machine for casting 125T motor rotors, suitable for rotor models Y132-Y180

Category:

Keywords:

Fully automatic dual-station aluminum die casting machine

Customer service hotline:

Product Features:

This equipment is a special aluminum casting machine for 125T motor rotor casting, suitable for rotor models Y132-Y180

1. High automation and easy operation can be achieved by simply manually adding iron chips; one-button operation.

2. All action pressure, speed, required functions, and parameters can be set and displayed via the touch screen, and executed with the assistance of a servo motor, pressure sensor, and PLC.

3. The equipment adopts a multi-station rotary table and is controlled by a numerical control system. It features high control precision and easy operation. The rotating tooling is driven by a high-efficiency, low-consumption Yaskawa servo motor.

4. An automatic false shaft exit mechanism is added to achieve an integrated rotor aluminum casting process. The main technical parameters are automatically generated and can save 20 preset process parameters.

5. The left and right sides of this machine's protective doors are fixed. The exterior can be equipped with aluminum profiles and sheet metal doors to form an enclosed space, and it is equipped with a smoke collection device.

6. The left and right sides of this machine's protective doors are fixed, while the front and rear are pneumatic up-and-down moving. An enclosed space is formed by the outer sheet metal, and it is equipped with a smoke collection device.

7. The components used in this machine all meet national standards and have advantages such as high performance, easy maintenance, and easy procurement.

8. The machine body frame adopts a welded structure, and the main board, etc., are welded with steel plates and then undergo stress treatment. The surface of the equipment is sandblasted and painted.

Based on the functional characteristics of the vertical pressure casting machine, our company has specially designed a hydraulic system that can effectively reduce motor power, saving 50-80% energy compared to conventional aluminum casting machines, and has advantages such as easy procurement of sealing materials.

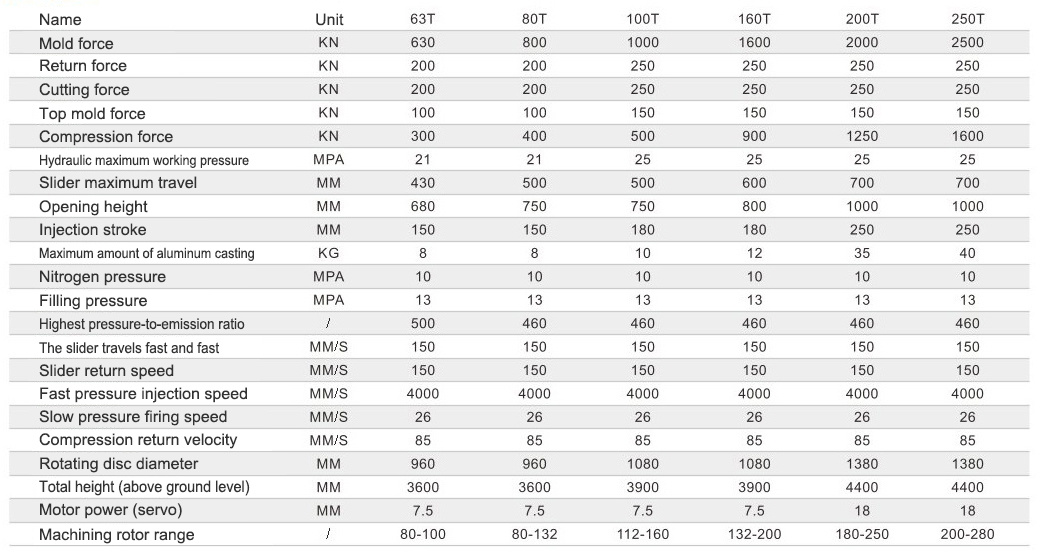

Technical Parameters:

Previous page

Previous page

More products

Inquire now

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!